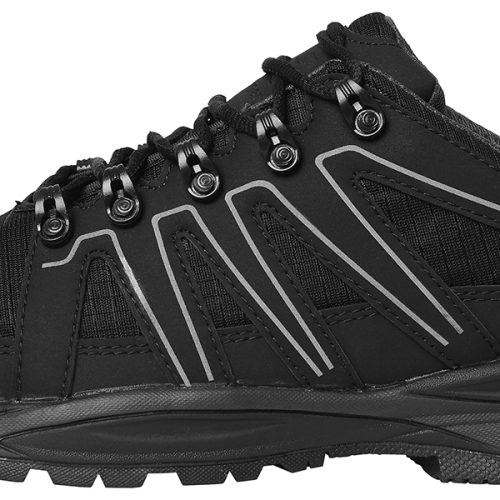

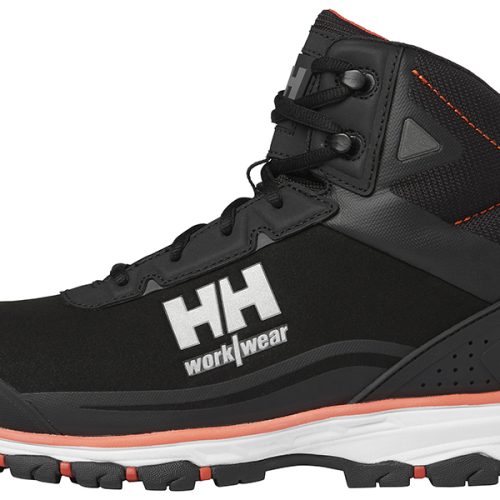

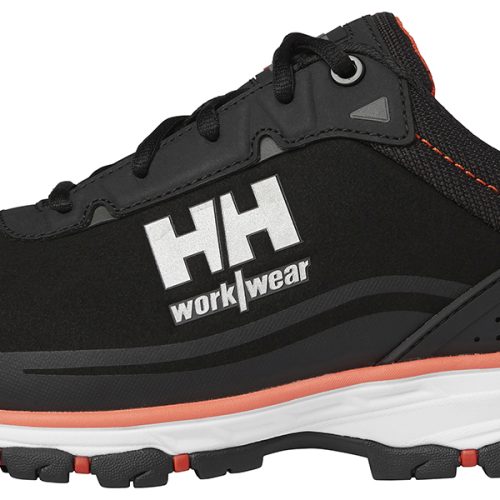

The Helly Hansen footwear range gives you functionality, style and trust, but most of all, their products give you confidence that your toes are safe and snug in all working conditons.

MENUMENU

- Schoolwear

- Appointment Booking

- National Schools

- Bandon Primary School

- ETNS Carrigaline

- Educate Together NS - Paradise Place

- ETNS Rochestown

- Gaelscoil Charraig Ui Leighin

- Gaelscoil na Duglaise

- Gaelscoil Chionn tSáile

- Holy Well NS - Carrigaline

- Minane Bridge NS

- Rockboro

- Scoil an Athar Maitiú GNS - Togher

- SONAS NS - Carrigaline

- Beaumont GNS - Scoil Barra Naofa

- Scoil Bhride GNS - Crosshaven

- Scoil Mhuire Junior School - Cork

- Secondary Schools

- School/College Hoodies

Do you love your uniform?

- Workwear

- Aprons

- Average Jo Workwear

- Chefwear

- Footwear

- Helly Hansen

Do you love your uniform?

Do you love your uniform?

- Teamwear

- Search